The Art Department at Rowlett High School needed a better slab roller for their ceramic classes.

My wife Diane Clegg is an Art teacher at Rowlett High School. She teaches sculpture and ceramics. They had an old clay slab roller that was broken, and essentially a worthless pile of scrap. This slab roller was a Shimpo model SRC slab roller which sells today for about $1200. This model is a poor mechanical design and I advise you to avoid at any price. I gathered up the pieces and promised to make them a better one. With a little investment of time and money, using the existing parts, this is the solution I came up with.

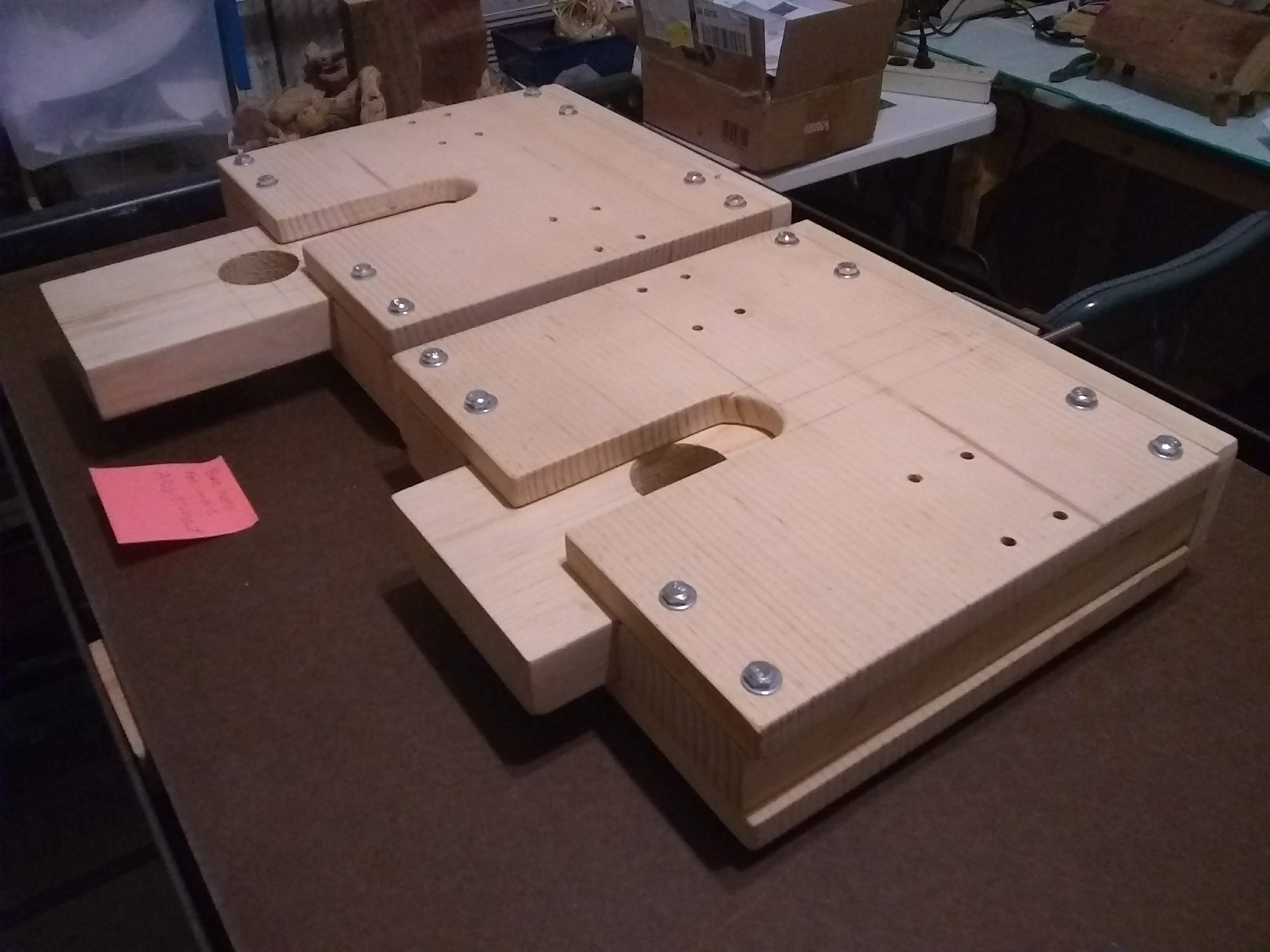

The Old Slab Roller in Pieces

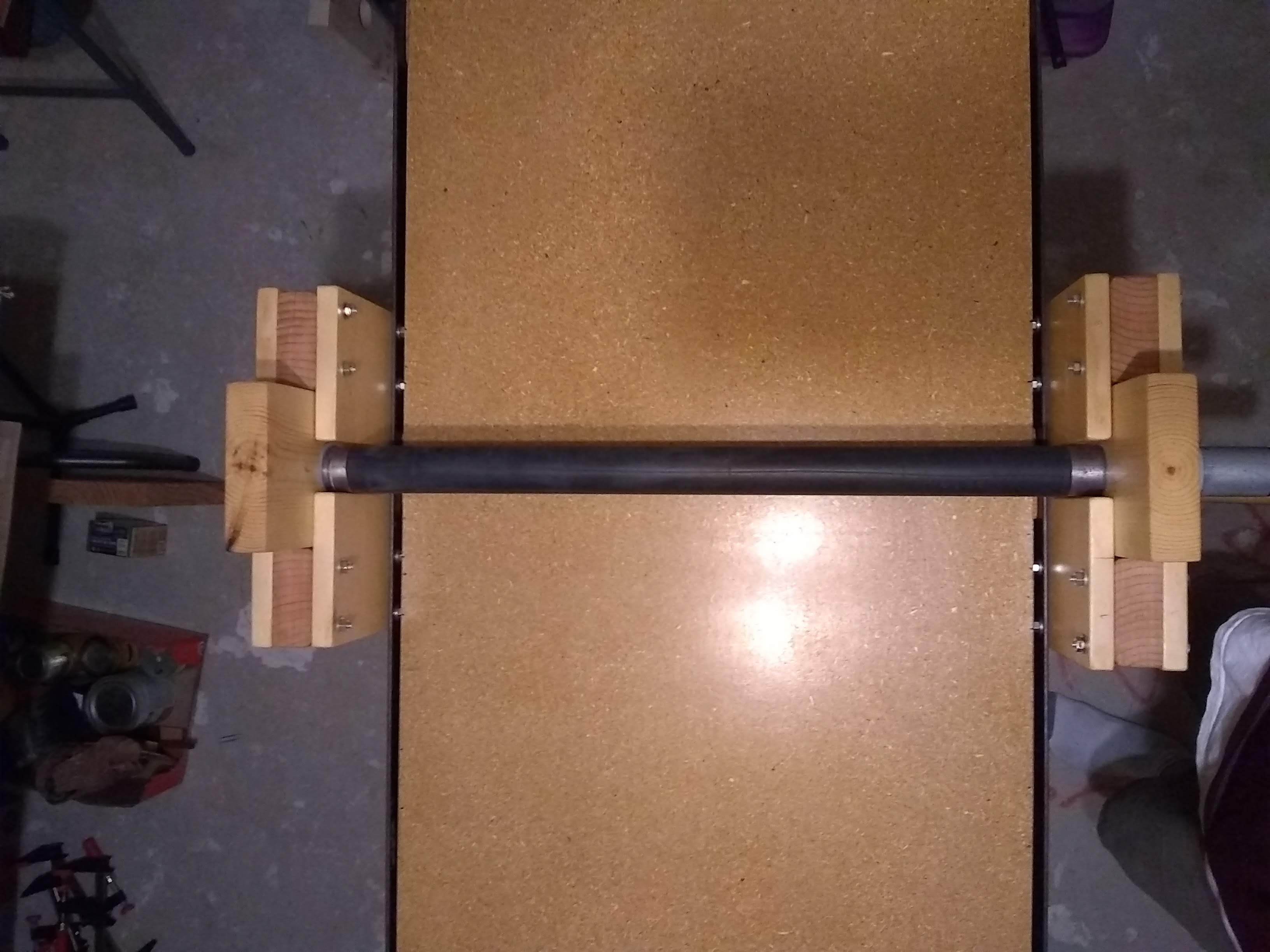

The first objective was to make the roller adjustable to create variable thickness of the slab. This is a critical value with this tool. I engineered a height adjust block that was sturdy and controlled with a simple turn screw mechanism. My first solution using 6mm lead screws failed because it was too lightweight. There is a tremendous amount of pressure employed flattening the clay and the 6mm screw was not strong enough for this application. The solution to the problem was using large 3/8″ steel bolts from Home depot to uses as the lead screw. The wider, top roller shaft was made from an old basketball goal. I had to make a custom axle for it using the existing roller shaft that had the crank handle welded to it. Converting the crank shaft axle, making it wider, took a lot of time and effort to center and spin accurately. I wanted to use a good set of bearings for the roller axles, but I could not find a set that fit the existing shaft diameters, therefore I tried using PVC pipe as a bearing, and it fit and rolled perfectly.

Engineering the Height Adjustment Block

At first, I tried to use just one roller for compression, but that design would not allow the slab to feed through the roller. Knowing it wouldn’t be the best solution, I tried anyway because of costs. Luckily, I found a conveyor roller online that matched the width of the table and it only cost $20. The fit was too tight to allow the roller to spin freely so I had to grind out some of the frame to make it work. The two roller mechanics is the best process by far for compressing the clay to make a uniform slab. The height adjustment that raises the top roller works great. Now the artist can roll out a uniform slab of clay as thin as 1/8″ which is very thin for ceramics.

The Final Product

I created a new two part wood deck to accommodate the bottom and top roller design. Here are some pictures of the parts and work involved in the process of converting a piece of junk into a working machine. I must admit it took a lot more time and trails than I anticipated, but that is to be expected when trying to make a better design using existing parts and no budget. It took some time looking for parts and tools to make my idea work, but in the end it all came together very nicely and I learned a great deal about machine mechanics. Now the students have a good working slab roller that will last along time.

This project was about deconstructing the existing tool and making it better, improving the outcome to make a perfect clay slab with the ability to make variable thickness of the clay material to suit the artist needs.

Re-engineering existing machinery can be challenging but deconstructing and exploring better methods is educational and rewarding.

Slab forming is a wonderful technique to make a variety of forms with clay with unlimited possibilities.